- All products

Cables86 products

Case Accessories55 products

Cases64 products

- Absolute Case4 products

- Arterial 22 products

- Case Customisation2 products

- Desks2 products

- Discontinued12 products

- Flight Cases2 products

- Phantom 2 Case3 products

- Phantom Case1 product

- SC Test Bench2 products

- Spectre 2.01 product

- Spectre 3.0 Integra & Proxima Water-cooling Cases10 products

- Spectre 4 Water-cooling Case8 products

- Spectre Enterprise Water-cooling Case6 products

- Spectre Integra-M Water-cooling Case10 products

- Stream Water-cooling Case3 products

- Systems1 product

Distribution Plates27 products

PowerBoard53 products

Water Cooling46 products

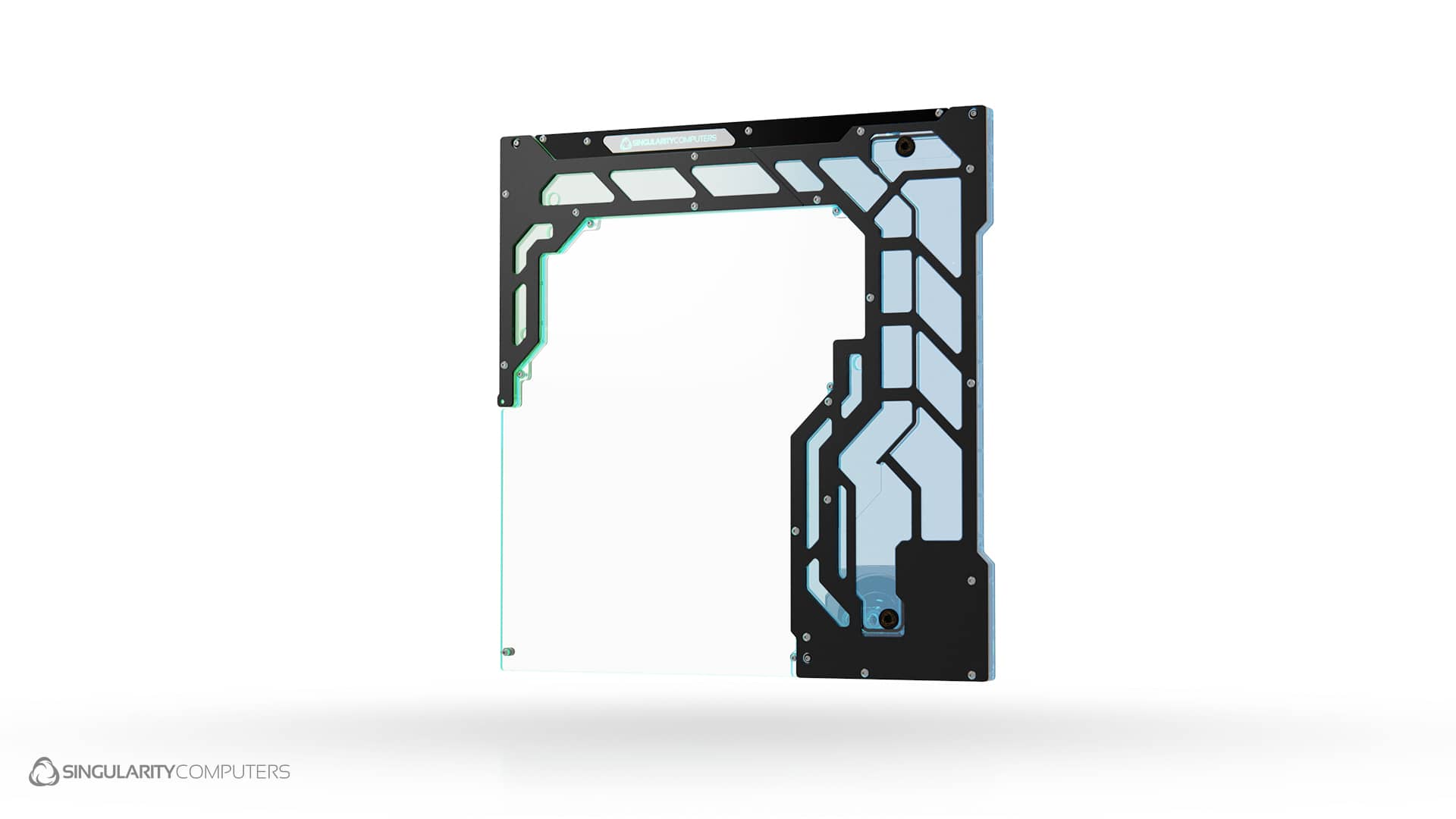

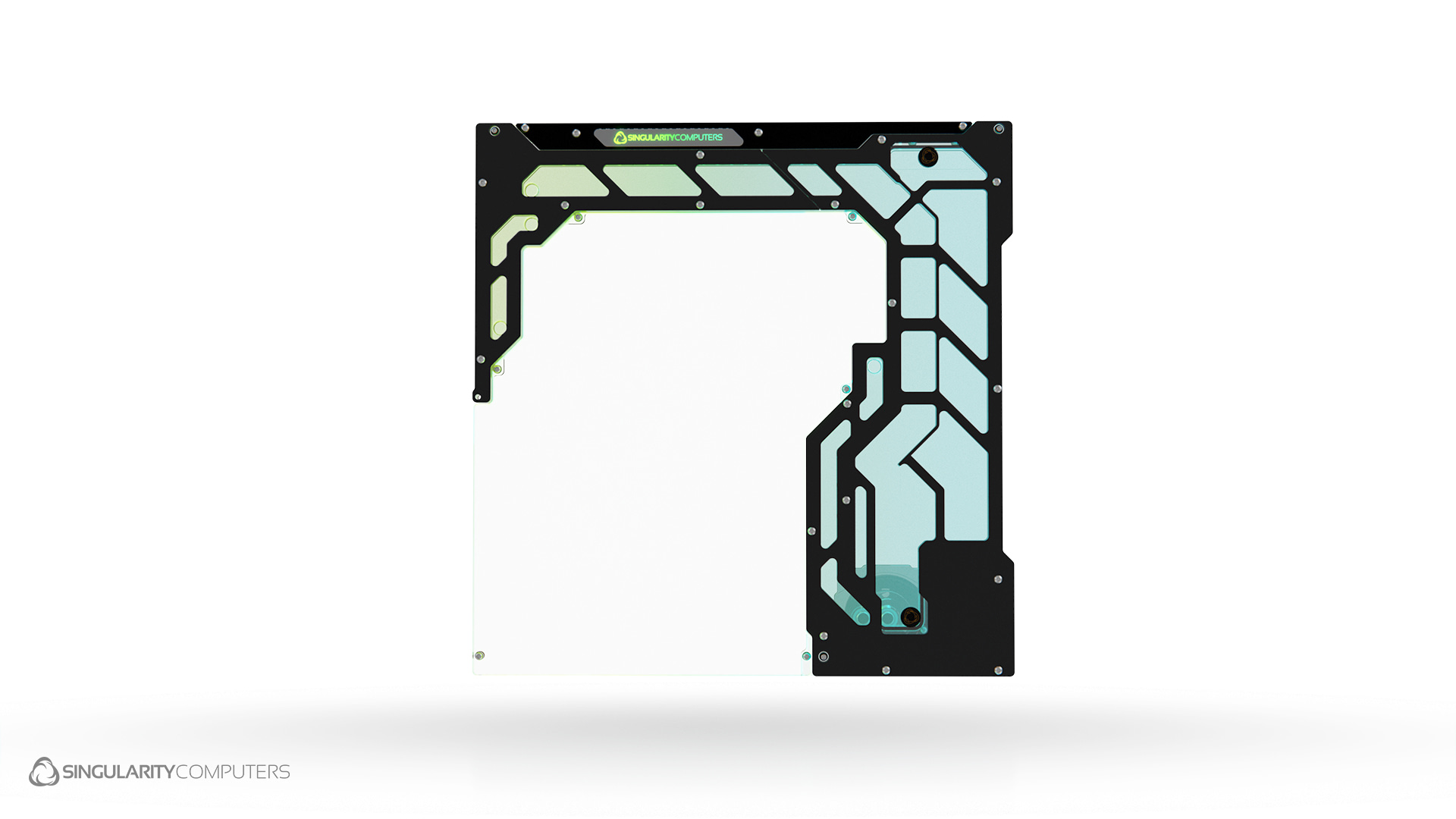

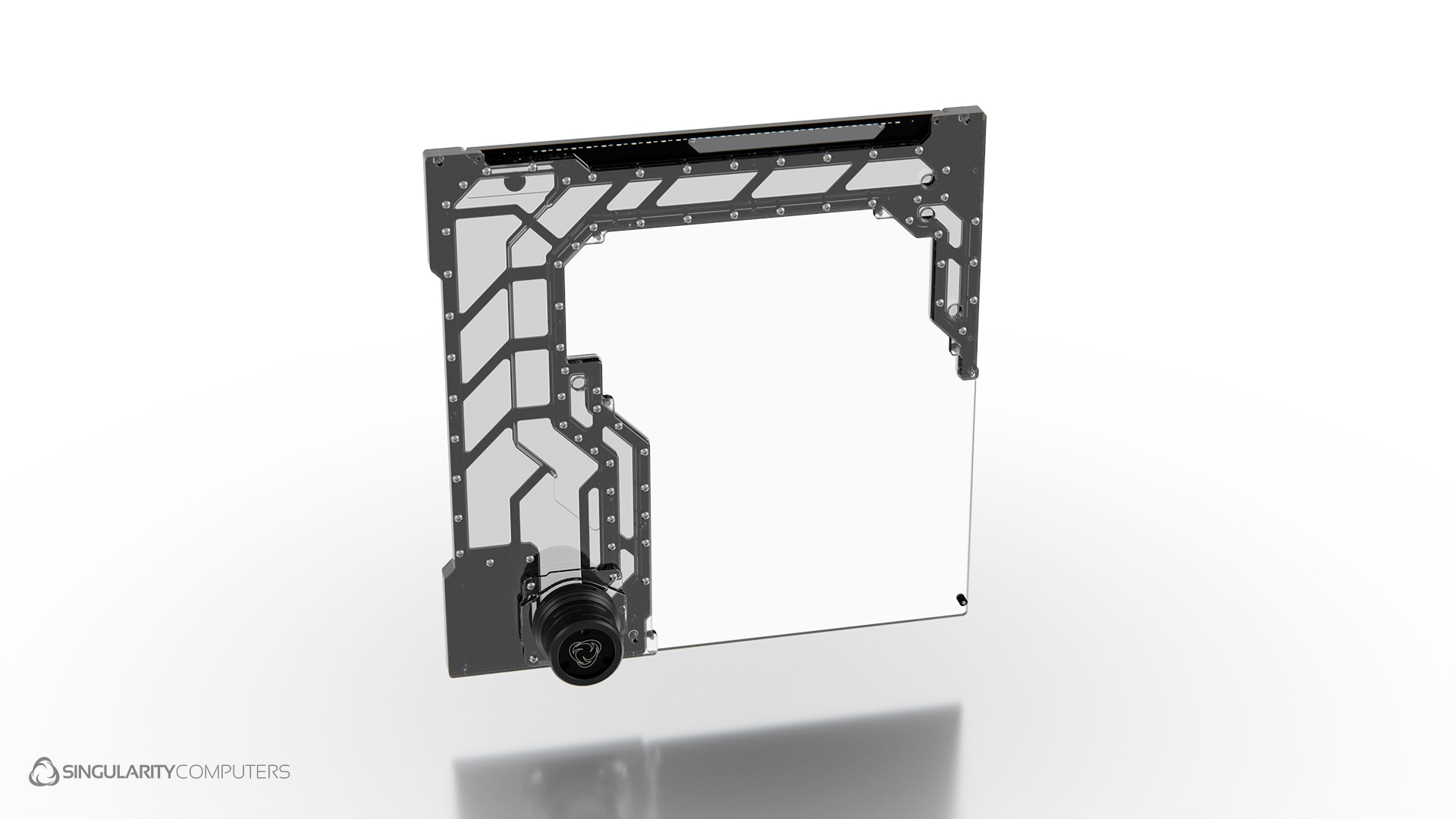

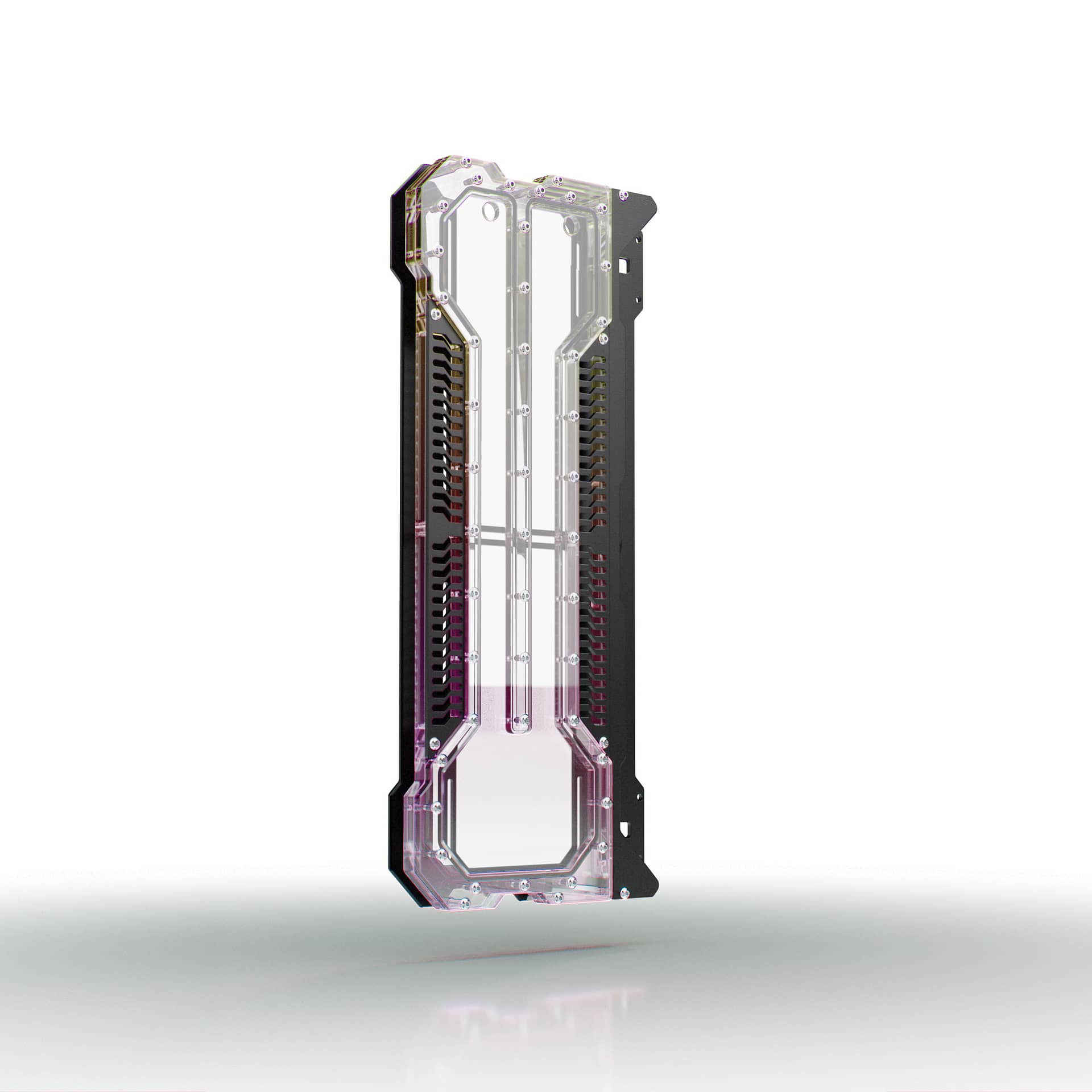

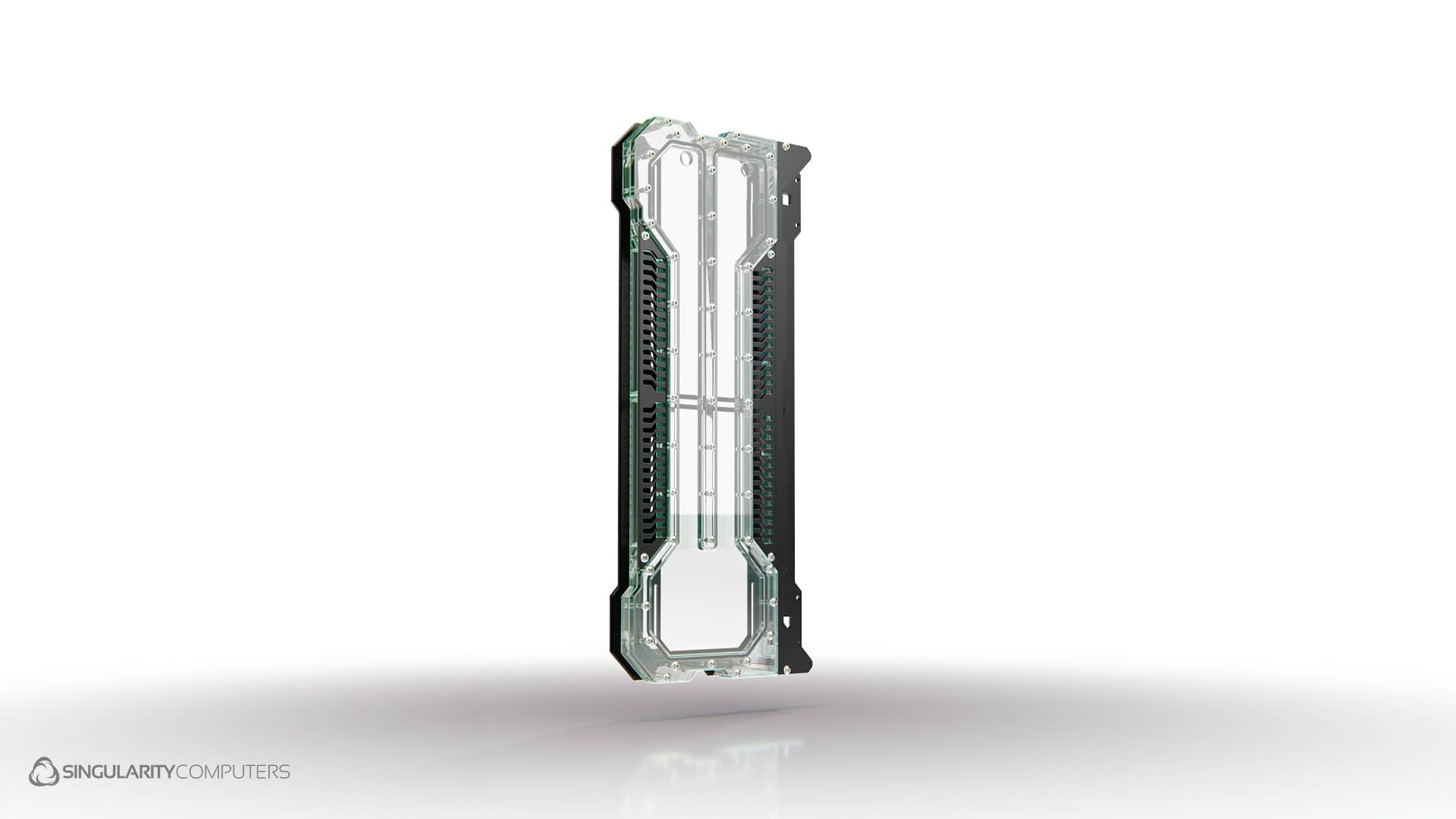

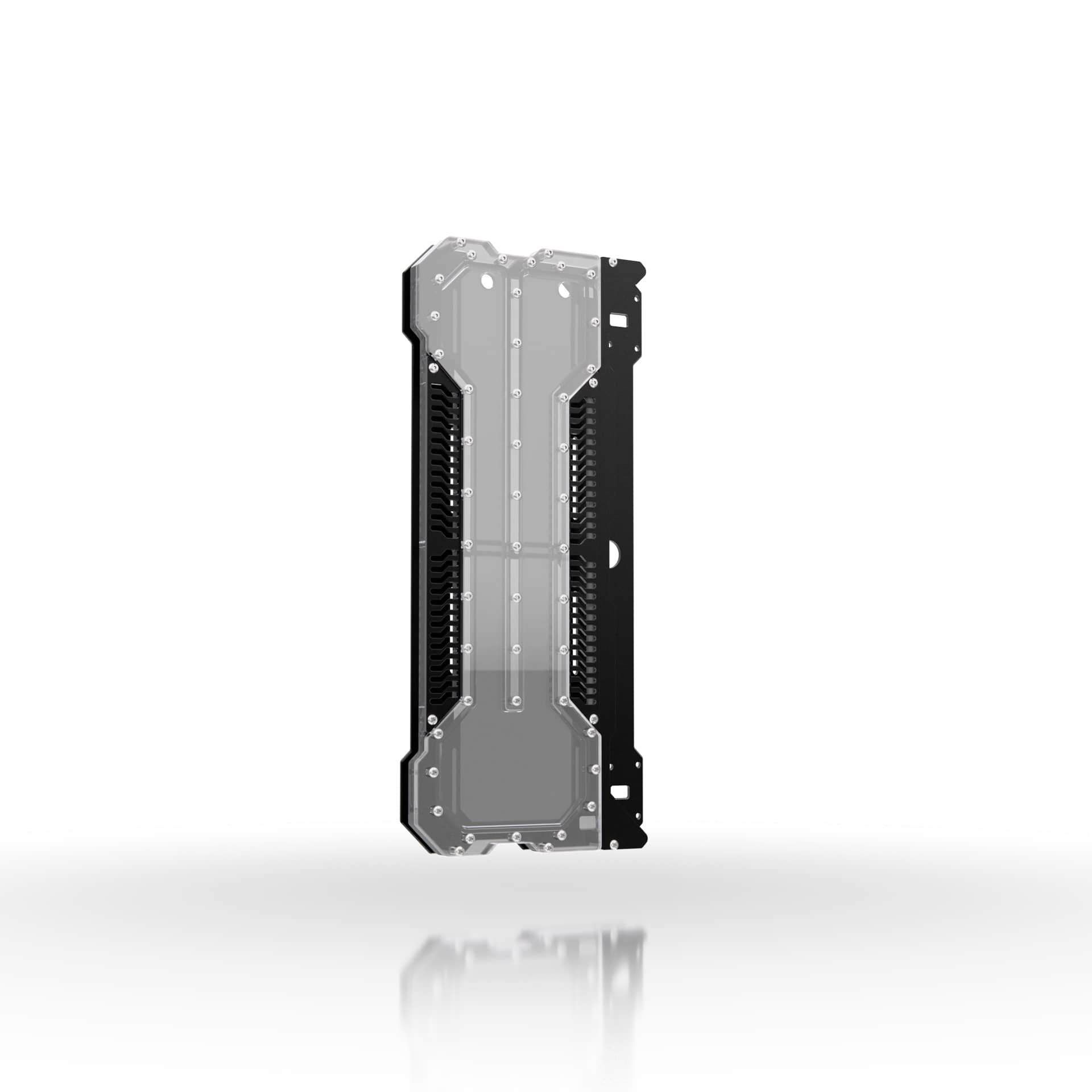

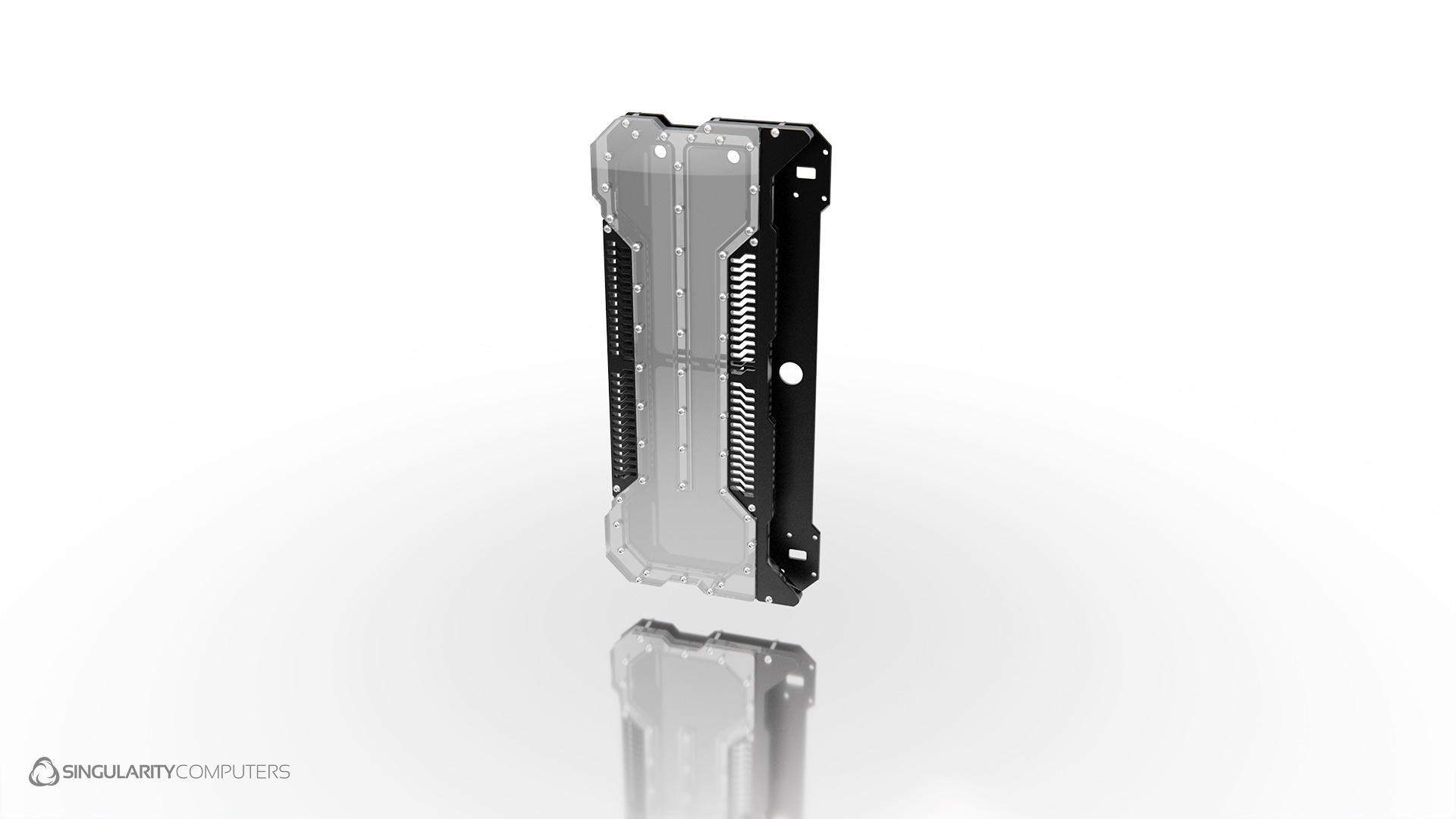

Spectre Integra-M Dual Loop Side Panel Dark

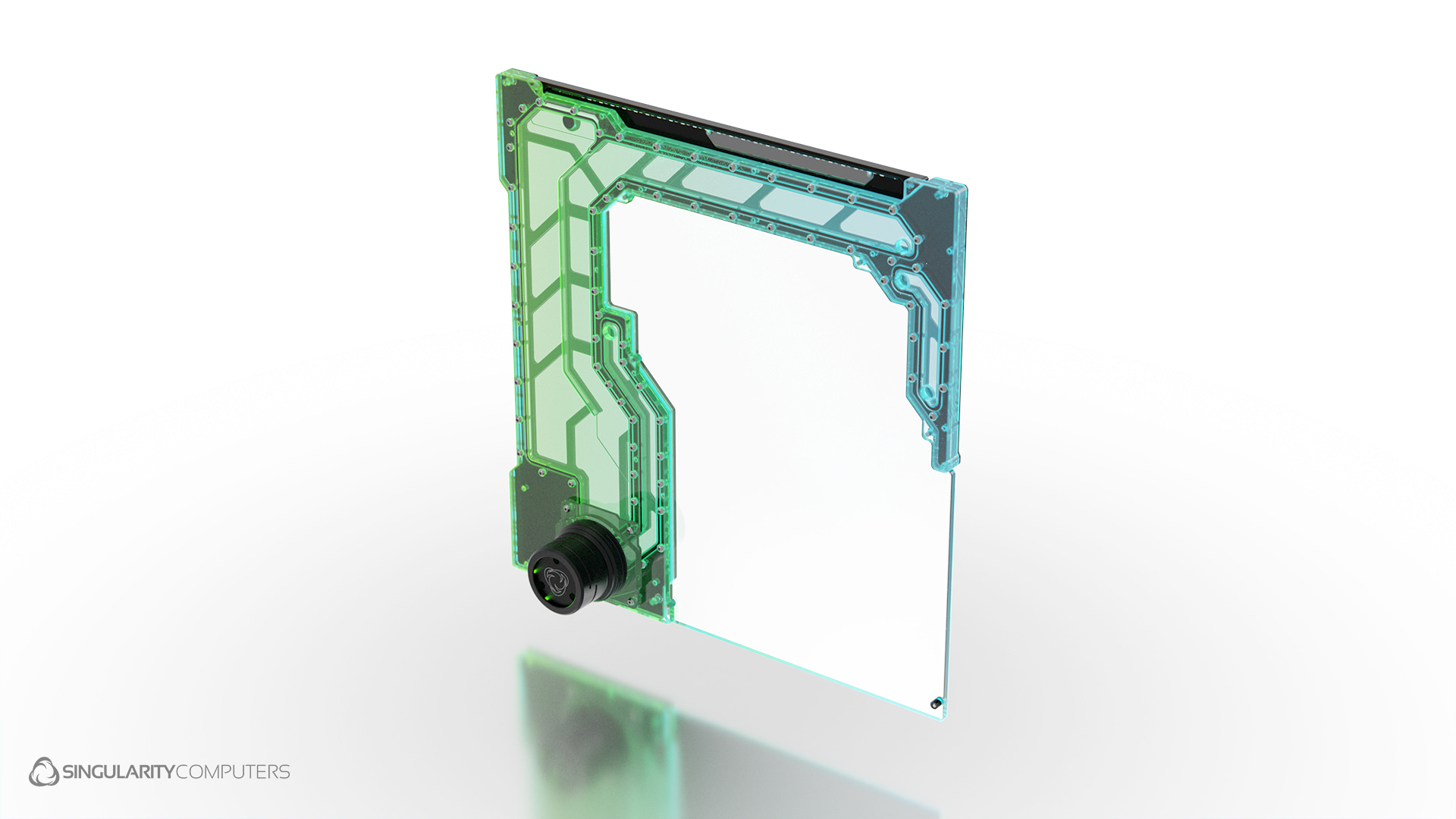

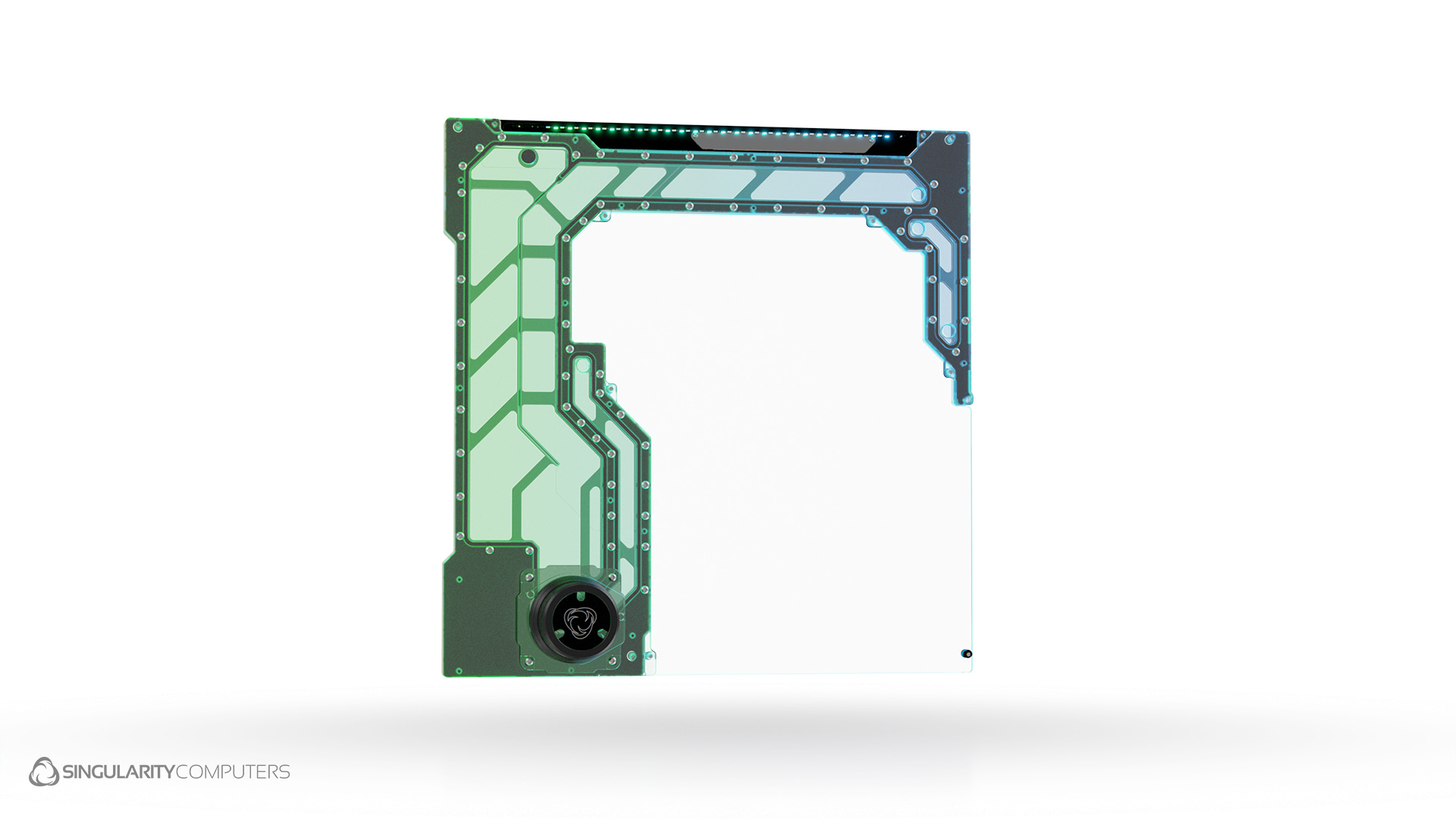

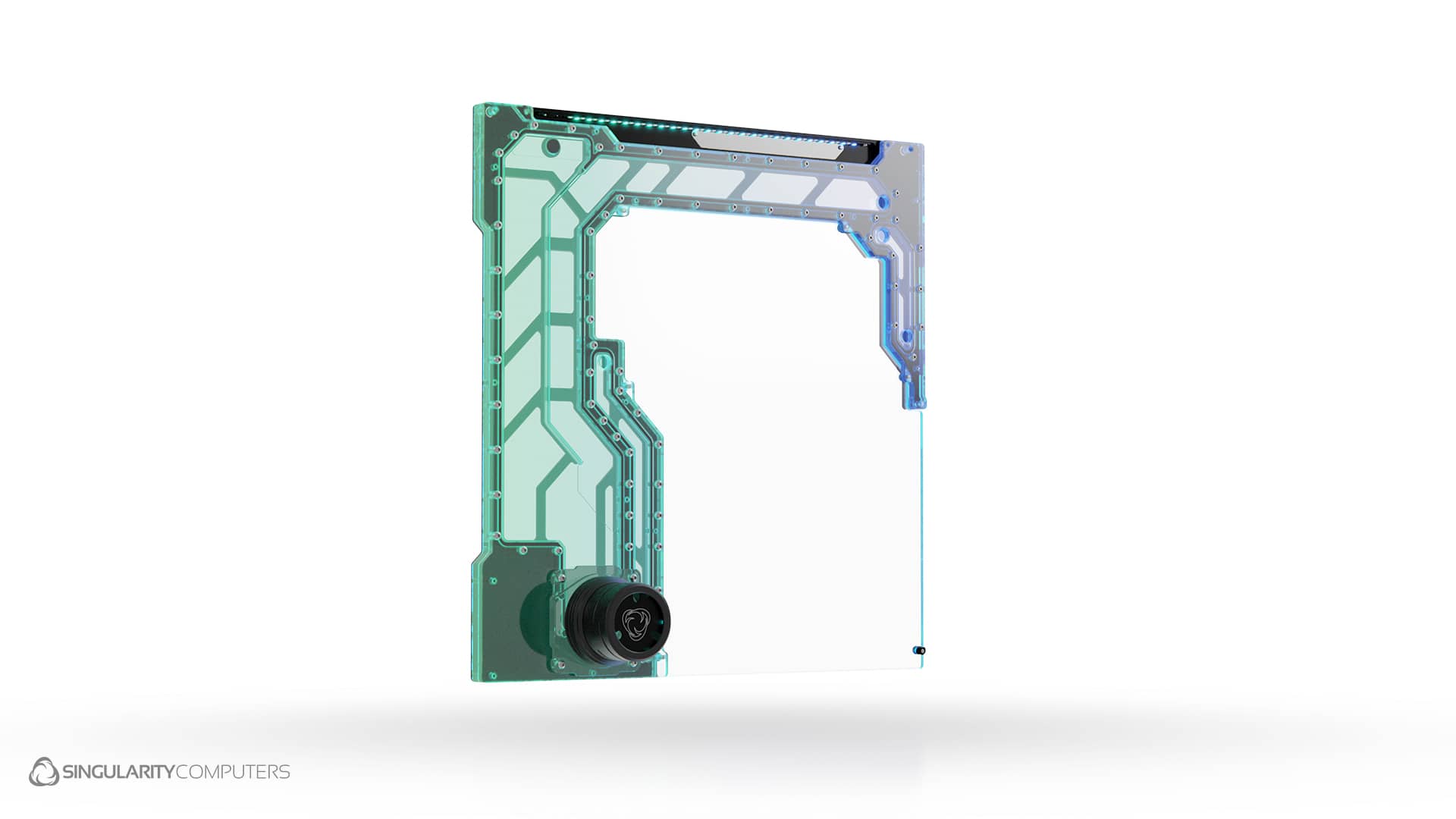

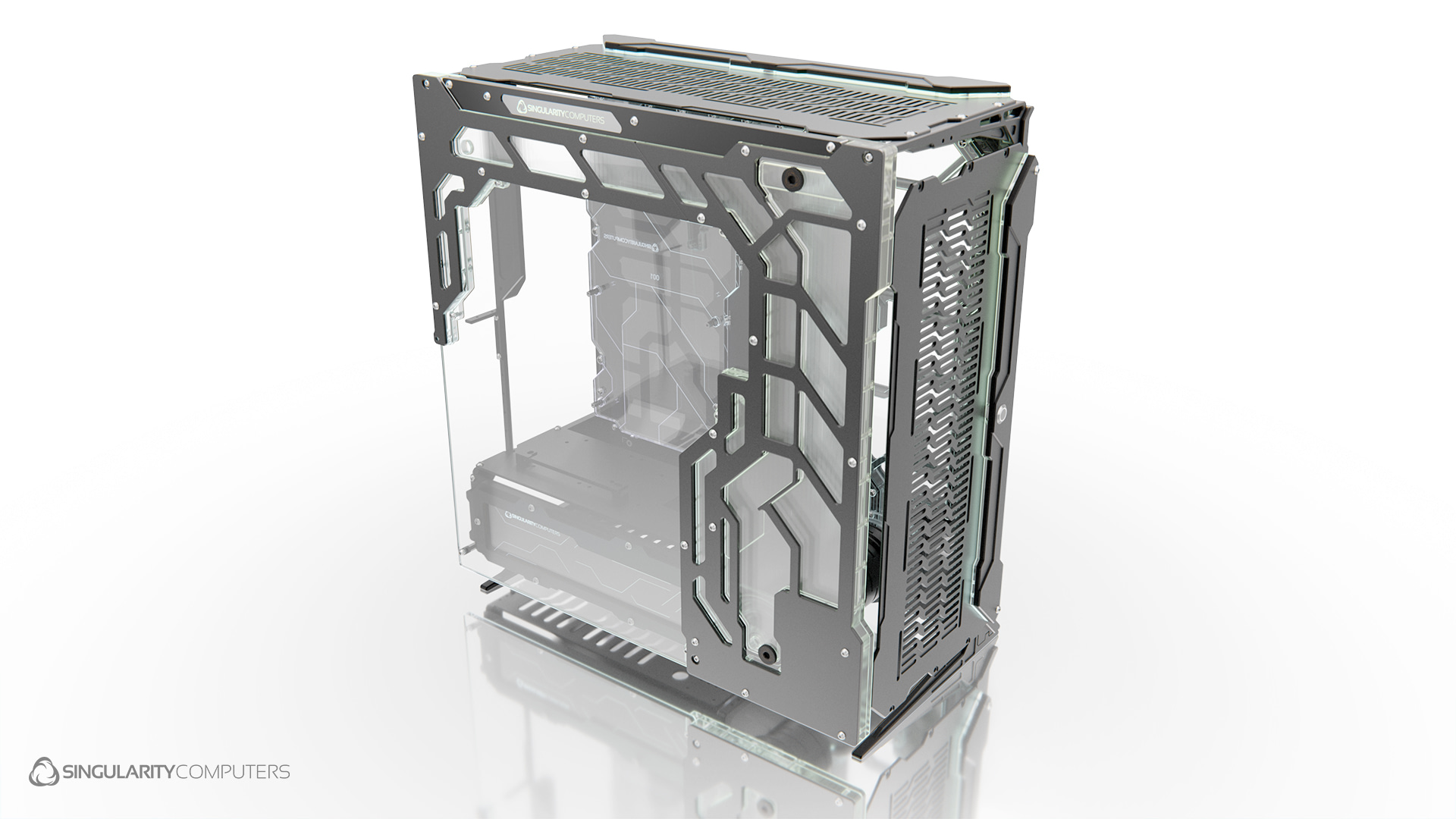

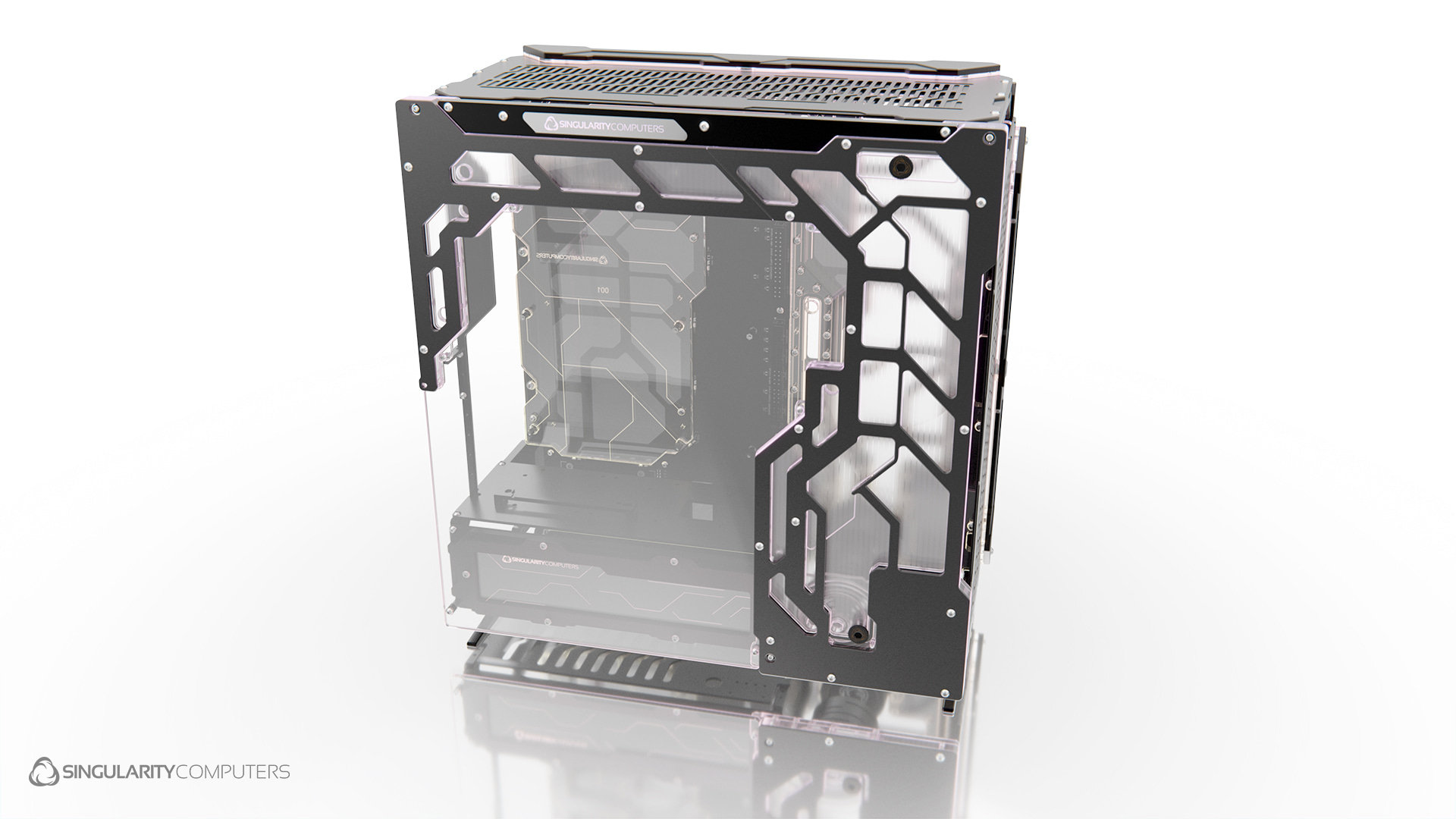

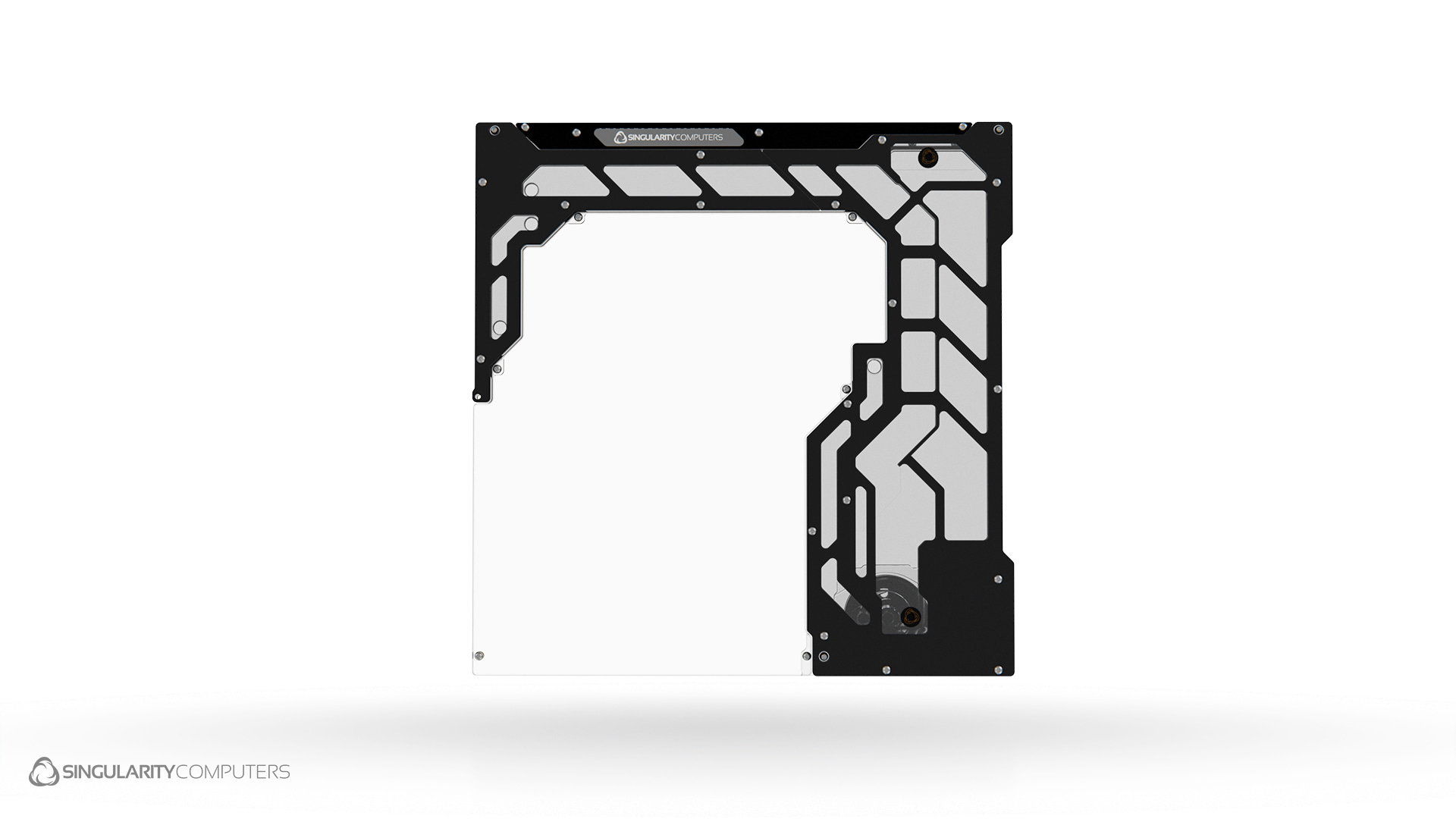

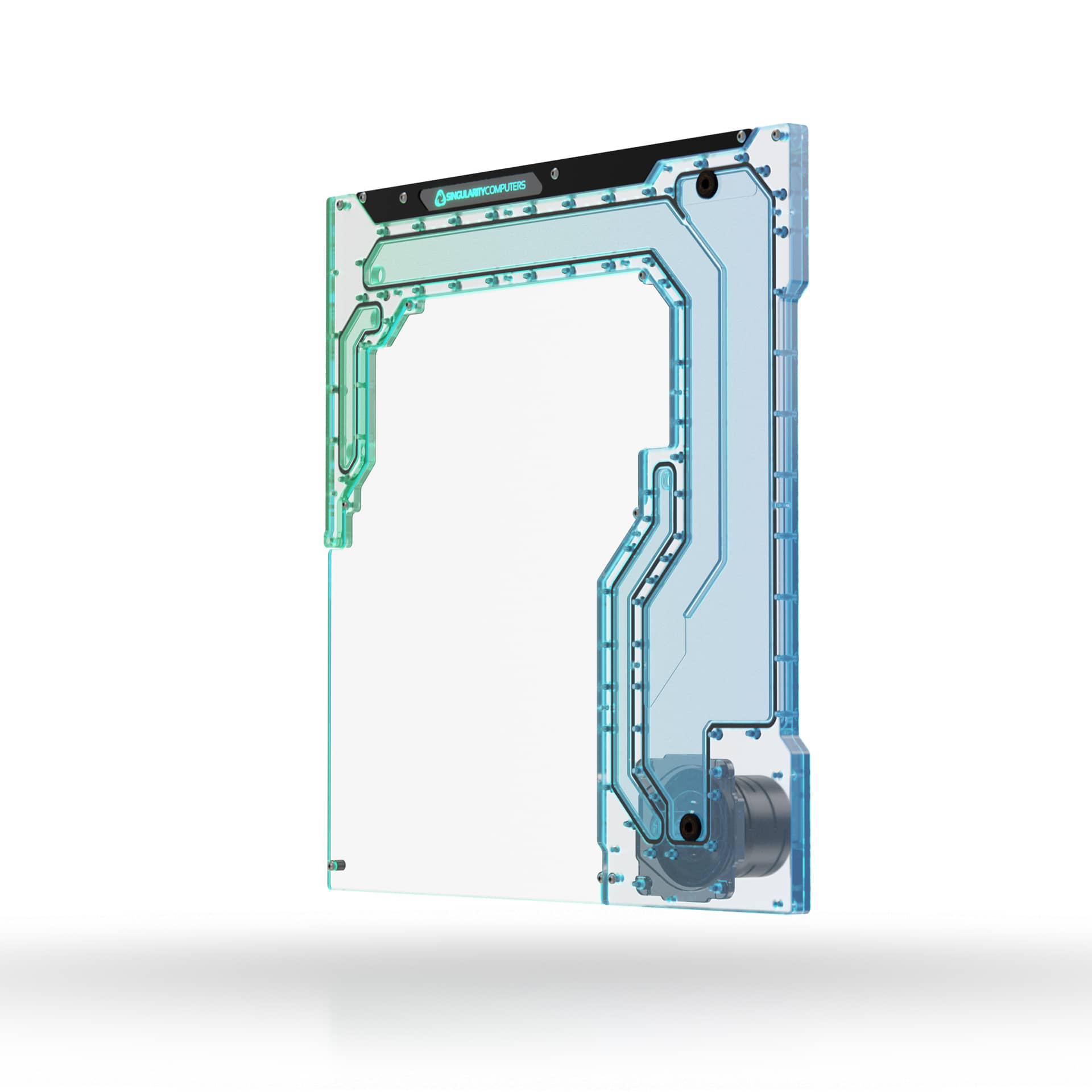

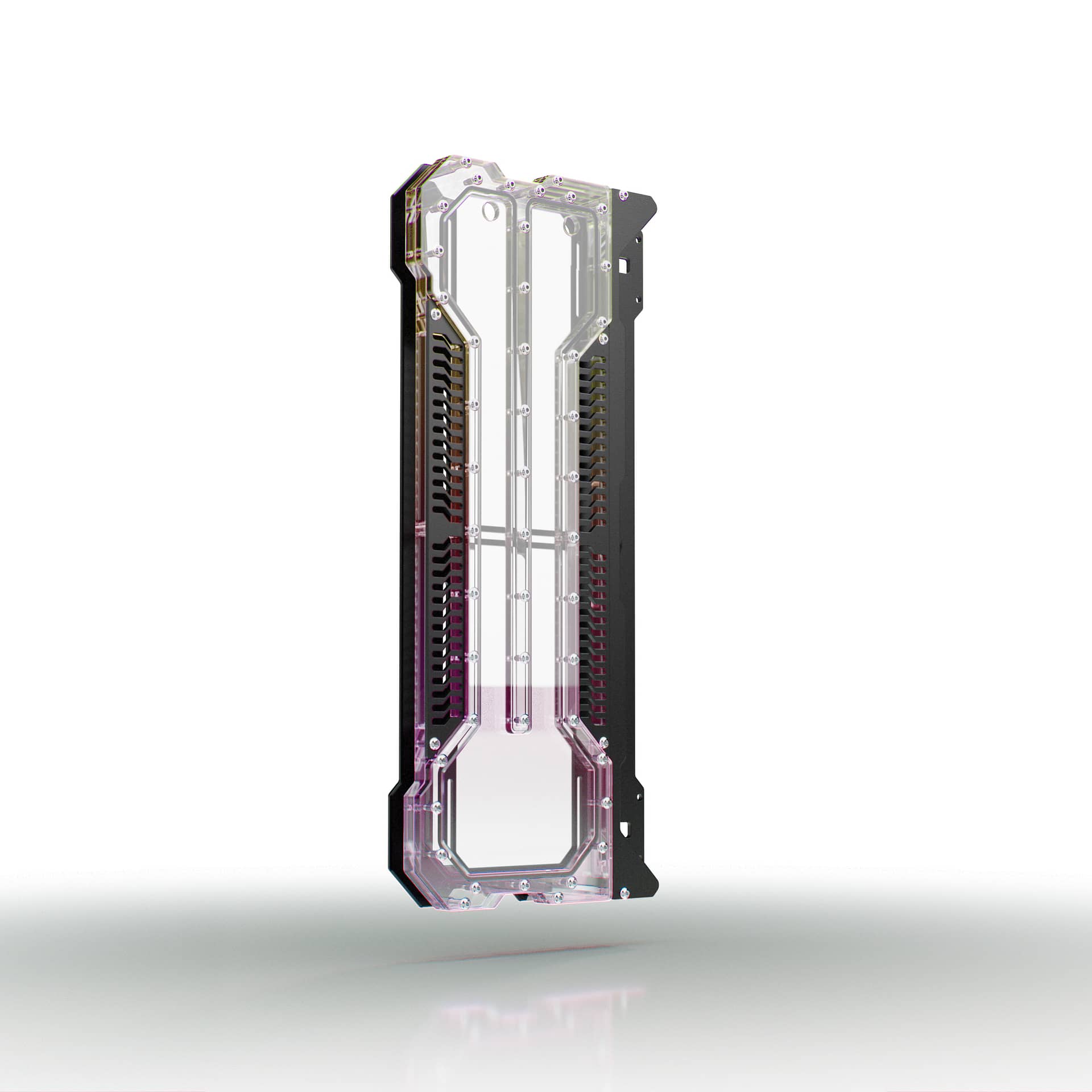

The Spectre Integra-M Dual Loop Side Panel is an addon for any version of Spectre Integra-M including Spectre Integra-MA. Essentially it is a mirror image of the main distribution plate, but with some port location and design changes to allow for one loop to be used for the CPU, and the other loop for the GPU/s. It is a replacement for the side panel window and mounts directly onto the side panel window mounts. It is designed to be as open as possible so that you can still see the most important parts of the build. The distribution plate section only covers the sides of the radiators and fans. It has an extra removable side panel so that it is easy to gain access to the case for loop building while the Spectre 3.0 Dual Loop Side Panel is installed. It has an integrated D5 pump top, Protium 3.0 Pump Cover and two ARGB LED strips which come pre-installed. There are 4 ports which are positioned for the GPU loop and top radiator, and a fill and drain port. The main case distribution plate layout works perfect for the CPU loop connected to the front radiator. The Spectre 3.0 Dual Loop Side Panel can be used in dual loops, single loop series or parallel. The Spectre 3.0 Dual Loop Side Panel is built from two layers of clear acrylic. We have also created Spectre Integra-M Dual Loop Side Panel Dark which is built from a grey tinted layer of acrylic, a clear layer and a satin black cover layer.

US$439.00

Specifications:

Integrated Reservoir, Pump Top, Pump Cover, Fill Port, Drain Port, Parts of water-cooling loop.

Ports: x6 G1/4” BSPP. 1x Fill Port. 1x Drain Port.

Pump: (Not included): Compatible with all D5 pumps.

D5 Pump Cover: Protium 3.0.

LED Strips: x2 50cm 5V ARGB LED Strips with 50cm cables.

Package Dimensions: L: 536mm H: 578mm W: 180mm.

Package Weight: 4kg.

Product Dimensions: L: 486mm H: 528mm W: 130mm.

Product Weight: 3kg.

Materials: Cast Acrylic.

Manufacturing Process: CNC Router.

Assembly: Assembled by Hand.

Testing/Validation: All Distribution Plates are factory pressure tested and precise fastener tension is applied.

Installation:

Compatible with all Spectre 3.0 case versions including limited editions. Installs onto the Spectre 3.0 Side Panel Window Mounts like the stock side panel but with longer fasteners which are included. It also attaches to the top rear IO mounting hole using an included stand off and fasteners. The distribution plate layout is designed for a single loop, dual loops, series, or parallel. For dual loops the main distribution plate of the case can be used for the CPU loop with the front radiator, and the Spectre 3.0 Dual Loop Side Panel can be used for the GPU loop with the top radiator. There are many ways to route the tube for a single loop, series or parallel.

Experience Singularity:

We create the products we want in our builds based on our 15 years of experience building high end computers. All our designs begin with function, versatility is vital to increase the possibilities so that you can create the build you want to, something unique. Our products are premium, we do not hold back on quality to save cost. All our products use the most high-end available materials and manufacturing processes. Our vision is to continue to introduce unique and exciting ideas, to inspire and lead the industry.